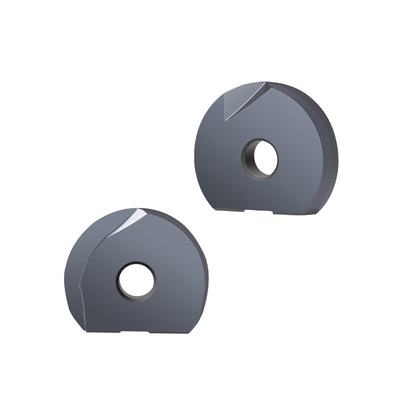

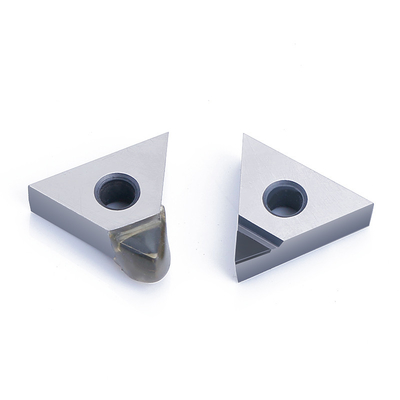

Jarum Koiling Karbida untuk Mesin Penggulung Baterai Lithium Komponen Cetakan Pukulan Presisi Tinggi

Bidang Aplikasi

Jarum penggulung karbida adalah komponen penting dalam mesin penggulung produksi baterai lithium. Dengan pertumbuhan pesat kendaraan listrik, permintaan akan komponen efisiensi tinggi seperti ini telah meningkat secara signifikan, terutama untuk baterai lithium energi baru.

Detail Produk

- Perawatan Permukaan: Disesuaikan sesuai spesifikasi

- Akurasi: Presisi disesuaikan dengan kebutuhan (kemampuan ±0.001 mm)

- Material: Badan jarum tungsten karbida dengan kepala HSS untuk kinerja biaya yang optimal

- Kustomisasi: Sepenuhnya dapat disesuaikan dengan gambar CAD atau 3D yang diperlukan untuk pesanan non-standar

Properti Material

| Material |

Properti Material |

| Karbida |

Karbida semen adalah komposit metalurgi serbuk yang menawarkan kekerasan, ketahanan aus, dan stabilitas termal yang luar biasa. Meskipun lebih sulit untuk dikerjakan dan lebih mahal daripada baja cetakan, umur pakainya jauh lebih lama. |

| HSS |

Baja kecepatan tinggi memberikan ketahanan abrasi dan ketangguhan yang unggul, ideal untuk produksi batch kecil atau aplikasi yang membutuhkan ketangguhan material tinggi. |

Teknologi Pemesinan

Kemampuan produksi kami meliputi penggilingan silindris, penggilingan melingkar internal, penggilingan profil optik, penggilingan datar, pemesinan ulir, pemotongan kawat kecepatan sedang, pemotongan kawat kecepatan rendah, dan pemesinan pelepasan cermin.

Mengapa Memilih Kami

- Teknologi Canggih: Mampu membentuk bentuk kompleks dengan presisi tinggi (toleransi ±0.003 mm)

- Pemrosesan Efisien: Siklus produksi singkat dengan jadwal pengiriman yang andal

- Jaminan Kualitas: Output berkualitas tinggi yang konsisten dengan kontrol kualitas yang ketat

- Kerahasiaan: Tiga langkah perlindungan dengan perjanjian NDA opsional

- Kapasitas Produksi: Beberapa lini produksi dengan peralatan canggih

- Hemat Biaya: Harga kompetitif melalui desain dan pemilihan material yang dioptimalkan

Dengan pengalaman spesialisasi selama puluhan tahun dalam material dan cetakan tungsten karbida, kami menggabungkan penelitian dan pengembangan dengan peralatan produksi kelas atas untuk memberikan solusi cetakan unggul yang menawarkan rasio kualitas-harga yang sangat baik.

Kriteria Kualitas

- Ketahanan Aus

- Presisi

- Ketahanan Korosi

- Kekuatan Dampak

- Ketangguhan

- Modulus Elastisitas dan Kekakuan

- Kekuatan Patah Melintang

FAQ

Q1: Apakah Anda memproduksi cetakan pukulan khusus atau komponen die pukulan?

A: Ya, kami mengkhususkan diri dalam fabrikasi cetakan khusus untuk berbagai aplikasi dan material yang menuntut.

Q2: Apakah Anda menerima pesanan sampel volume rendah? Berapa MOQ Anda untuk kustomisasi?

A: Kami menerima pesanan sampel (minimal 1 buah) dengan gambar CAD/3D yang diperlukan. Waktu tunggu sampel adalah 10-15 hari, dapat dinegosiasikan untuk persyaratan khusus.

Q3: Bagaimana Anda memastikan kerahasiaan?

A: Kami menerapkan tiga langkah perlindungan untuk semua informasi dan menawarkan perjanjian NDA berdasarkan permintaan.

Q4: Apa syarat pembayaran Anda?

A: Deposit 30% melalui T/T, dengan saldo 70% jatuh tempo sebelum pengiriman. Foto produk disediakan sebelum pembayaran akhir.

Q5: Produk apa yang dapat Anda beli dari kami?

A: Kami menawarkan sisipan karbida, end mill, bor, alat bor, alat potong, dan cetakan presisi yang disesuaikan.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!